Uthini umgaqo wokusebenza kumatshini womkhenkce? Kuqikelelwa ukuba wonke umntu akayazi le ngxaki. Eli nqaku liza kuchaza umgaqo wokusebenza kunye nokuhamba komsebenzi womatshini womkhenkce ngokweenkcukacha kunye nomzobo wesicwangciso.

Umkhenkce luhlobo lwesixhobo sokukhenkcisa esipholisa amanzi ngesikhenkcezisi senkqubo yefriji ukwenza umkhenkce. Njengoko kuboniswe kwi-Figure 1, isetyenziswa ngokubanzi kwiimveliso zasemanzini, ukutya, iimveliso zobisi, iyeza, i-chemistry, ukugcinwa kwemifuno kunye namanye amashishini. Ngophuhliso loluntu kunye nokuphuculwa okuqhubekayo kwinqanaba lemveliso yabantu, ishishini lomkhenkce liya liba banzi kwaye libanzi, kwaye imfuno yentlalo yoomatshini bomkhenkce nayo iyakhula.

Ⅰ. Intshayelelo emfutshane yomgaqo wokusebenza

Umgaqo wefriji we-ice maker uboniswe kulo mfanekiso ulandelayo. Isikhenkcezisi sixinzelelwa yicompressor kubushushu obuphezulu kunye negesi yoxinzelelo oluphezulu, ipholiswe yicondenser, ifakwe ulwelo kubushushu obuphakathi kunye noxinzelelo oluphezulu, ixinzelelwe yinkqubo ye-throttling, emva koko iqukuqelele kwi-evaporator kwaye ikhuphe umbhobho wayo. Isikhenkcisi sifunxa ubushushu bemeko-bume esisingqongileyo ukuze sibe ngumkhenkce wamanzi, emva koko siphindele sibuyele kwicompressor ngombhobho wokubuyisela, emva koko sicinezelwe kwaye sikhutshwe. Lo mjikelo wenza amanzi abe ngumkhenkce de amagaqa omkhenkce afikelele kubunzima obuthile.

I-refrigerant ixinzelelwe kwi-high-temperature kunye ne-high-pressure gas kwi-compressor kwaye ikhutshwe, kwaye ingena ngokuthe ngqo kwi-evaporator ngombhobho wokuhambisa ubushushu, ukwenzela ukuba ubushushu be-evaporator buphakame, kwaye iityhubhu zomkhenkce ziwela kwi-evaporator phantsi kwesenzo esidibeneyo sefriji kunye namanzi ongezelelweyo. Emva kokugqiba inkqubo yokwenza umkhenkce kube kanye, qhubeka uphinda-phinda kuze kube yilapho iityhubhu ze-ice kwifriji zifunjwe ngokupheleleyo, kwaye inkqubo yokwenza umkhenkce iyanqunyanyiswa. Emva kokukhupha iityhubhu zomkhenkce, umenzi womkhenkce uyaqhubeka nalo mjikelo ungasentla.

1. Inkqubo yokwenza umkhenkce

Emva kokuba umatshini uvuliwe, faka iswitshi yomsebenzi kwi-"Ice Making 20". Ngeli xesha, ukukhanya kwesalathisi kuvuliwe, kunye nempompo yamanzi kunye ne-valve ye-solenoid ye-drainage inikwe amandla imizuzwana emininzi (ixesha elithile lingamiselwa) ukukhupha amanzi aseleyo kwitanki yamanzi, ngaloo ndlela uqinisekisa ukuba amanzi asetyenziselwa ukwenza umkhenkce ahlaziyekile kwaye acocekile. ibona ukuba iityhubhu zomkhenkce efrijini zigcwele na, ukuba umkhenkce awugcwalanga, qalisa i-compressor, qalisa i-condenser fan yokupholisa ngaxeshanye, vala impompo yamanzi kunye nevalve yokukhupha amanzi, kwaye uvule ivalve ye-solenoid yokungena emanzini ukuze ungene kwindawo yokwenza umkhenkce.

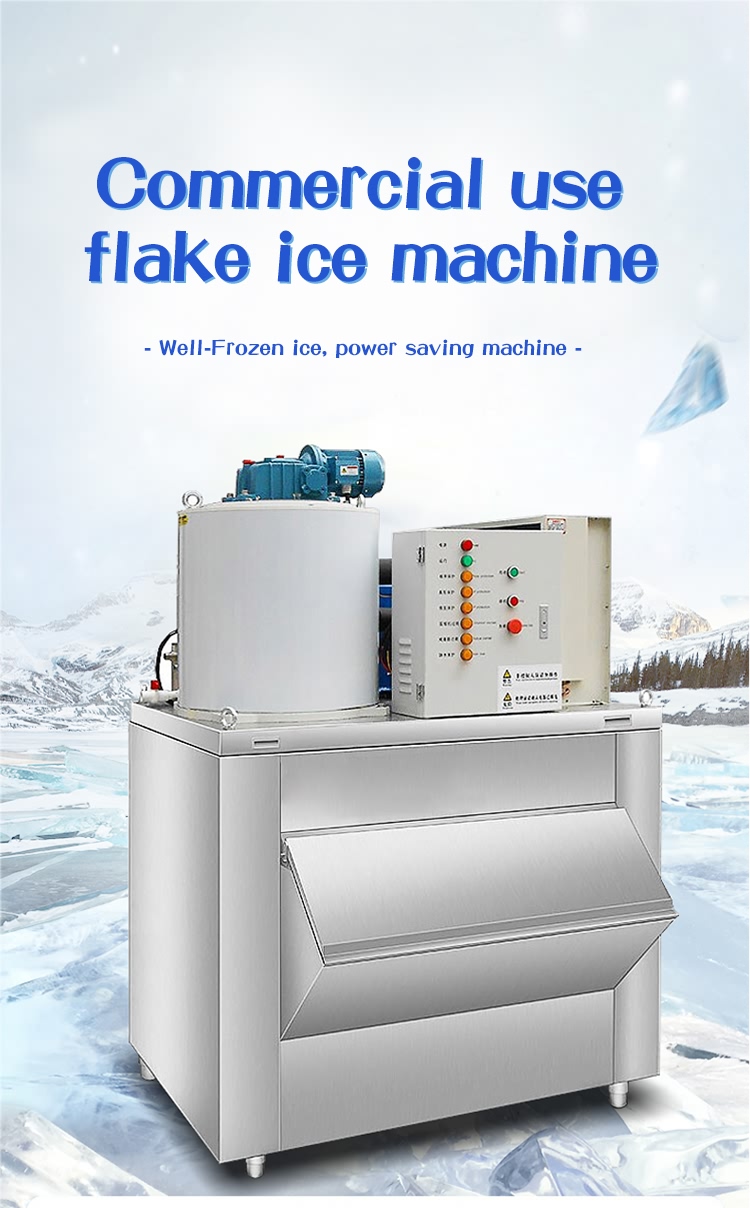

0.3T umatshini we-ice flake

Ngexesha lonke lenkqubo yokwenza umkhenkce kunye ne-deicing, i-compressor ihlala iqhuba, i-valve yegesi eshushu ivaliwe emva kokuba i-compressor iqalwe imizuzwana embalwa, impompo yamanzi iqalwa emva kokuba i-compressor ipholile kwigumbi lomkhenkce (i-evaporator) imizuzwana embalwa, kwaye i-valve yokungena kwamanzi ivaliwe xa umtshini wezinga lamanzi udibanisa amanzi kwindawo yokuhlambela imizuzwana embalwa kunye nesalathisi samanzi kunye nesixhobo sokulawula amanzi. izibane phezulu), okanye emva kwemizuzu emininzi yokungena kwamanzi ngokuqhubekayo. Ngaphantsi kwesenzo sempompo yamanzi kunye nesahluli samanzi, amanzi ahamba ngokulinganayo kwi-compartment nganye yegumbi lokukhenkceza. Ngokuqulunqwa kwee-cubes ze-ice, umgangatho wamanzi uhla kwaye isalathisi samanzi siyaphuma. Ngeli xesha, amanzi aya kuzaliswa kube kanye de isichongi somgangatho wamanzi sidibane namanzi imizuzwana emininzi, ukuze kuqinisekiswe ukuba kukho amanzi aneleyo okwenza umkhenkce.

Kwinkqubo yokwenza umkhenkce, ibhodi yokulawula i-elektroniki iya kuhlala ibona ubushushu be-condenser, kwaye emva kokuba ubushushu bayo bugqithise ubushushu obubekiweyo, iya kuqalisa i-fan yokupholisa i-condenser ngokukhawuleza ukunciphisa ubushushu bayo.

Kufanelekile ukukhankanya ukuba i-condenser fan yokupholisa kunye ne-compressor yomnye oomatshini bomkhenkce zilawulwa yi-contactor efanayo, kwaye i-switch switch idityaniswe kuthotho kwisekethe ephambili ye-condenser fan yokupholisa njengolawulo lokuqalisa lwe-condensing fan. Xa uxinzelelo lwe-condensing luphezulu kune-1.7MPa, i-fan condensing iqala kwaye ime xa ingaphantsi kune-1.4Ma:.

2. Inkqubo yokuqhawula

Xa i-detector yobukhulu bomkhenkce idibana nokuhamba kwamanzi (kungekhona umkhenkce) imizuzwana embalwa, ipompo yamanzi iyasebenza kwaye i-valve ye-solenoid ye-drain ivula ukukhupha amanzi kwi-sink (ixesha lokukhutshwa kwamanzi linokukhethwa ngokutshintsha ixesha lokucoca kwipaneli). Emva kokucoca ngokwexesha elibekiweyo, i-valve ye-solenoid yokungena kwamanzi, i-valve ye-solenoid yamanzi kunye nepompo yamanzi ivaliwe, kwaye ayisayi kusebenza ngexesha lenkqubo yokuqhawula. Ekuqaleni kokukhutshwa kwamanzi, i-valve yegesi eshushu iyavulwa, kwaye umphunga oshushu wefriji ugeleza kwi-evaporator ukutshisa i-ice cubes kwindawo ye-evaporator. Iityhubhu zomkhenkce zityibilika kwigumbi lokugcinwa komkhenkce zibe ziingceba phantsi kwesenzo somxhuzulane, kwaye ibhokisi yokutshintsha ivuliwe, iphelisa inkqubo ye-deicing, ize iphinde ingene kwindawo yokwenza umkhenkce.

0.5T umatshini ice ice

3. Ukucima ngokuzenzekelayo xa umkhenkce ugcwele

Xa inkqubo yokuvuna iqhwa igqityiwe kwaye ifriji igcwele, ukukhanya kwesalathisi sokutshintsha kwebhokisi kuphuma ngeli xesha, kwaye umenzi weqhwa uyeka ukusebenza emva kwemizuzwana embalwa.

Ixesha lokuposa: Sep-17-2020